Position:Home >> Product >> Butterfly Valve >> PTFE-lined Butterfly Valve

Position:Home >> Product >> Butterfly Valve >> PTFE-lined Butterfly Valve

Product Introduction

Product Introduction

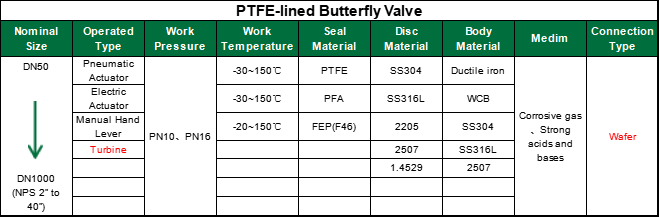

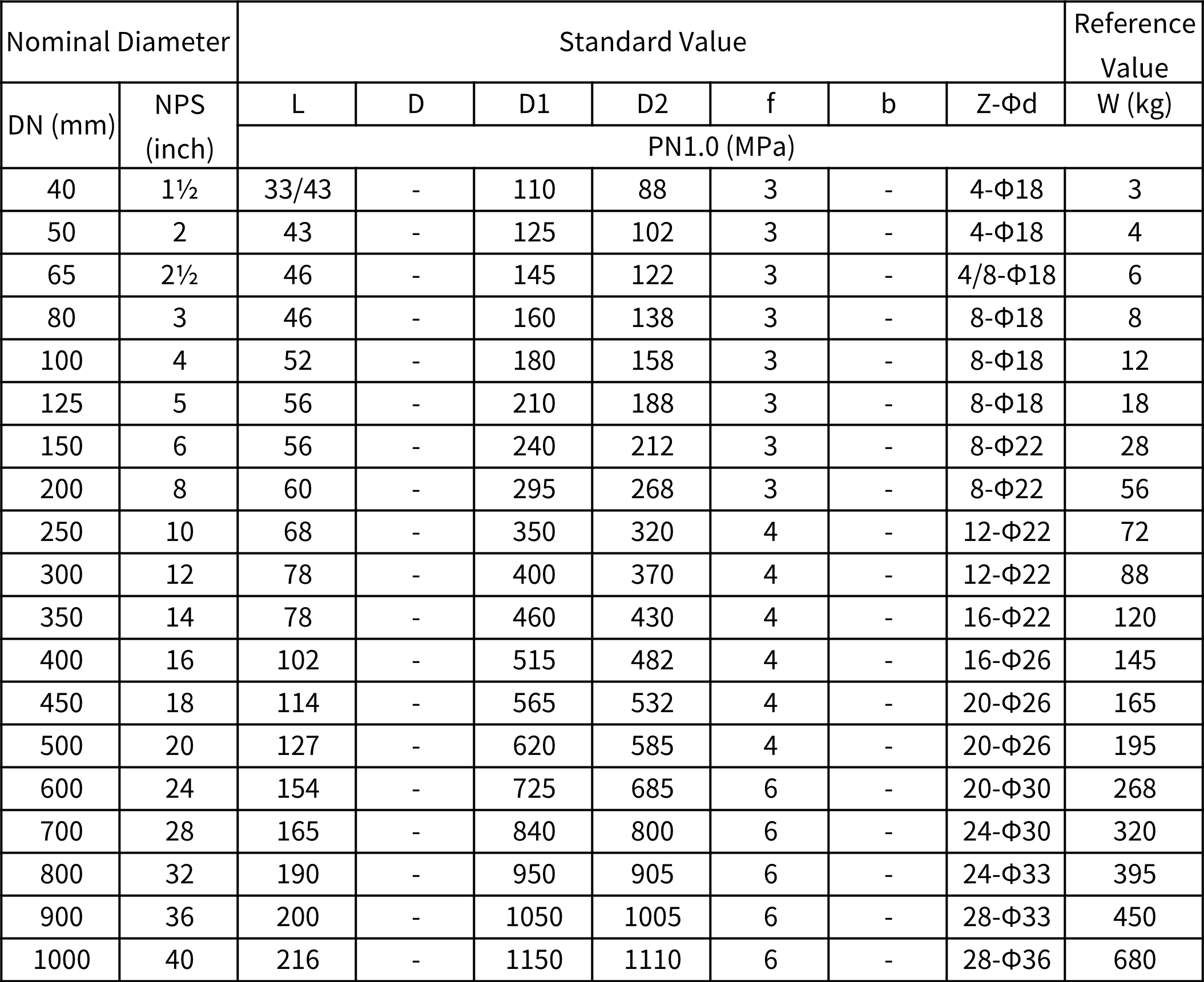

The wafer PTFE-lined butterfly valve features a full fluoropolymer lining (PTFE or PFA) that isolates the metal body and internals from the flowing media. It ensures excellent chemical resistance, tight shutoff, and long service life, especially in corrosive or aggressive environments. The...

Category

Category

News Center

News Center

The wafer PTFE-lined butterfly valve features a full fluoropolymer lining (PTFE or PFA) that isolates the metal body and internals from the flowing media. It ensures excellent chemical resistance, tight shutoff, and long service life, especially in corrosive or aggressive environments. The lining can be extended to the flange surface, eliminating conventional gaskets.

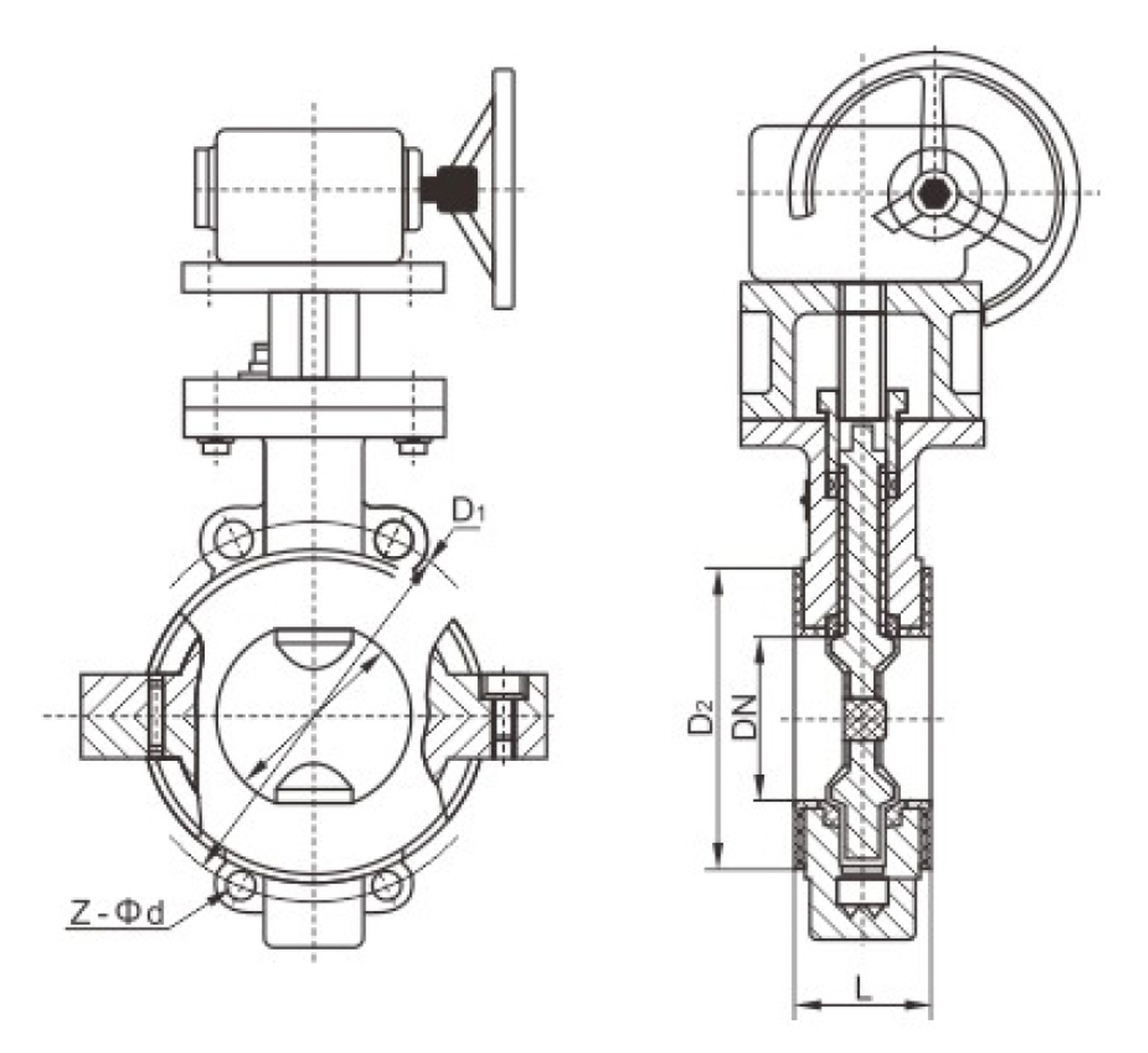

To meet diverse control needs, YEKE provides you with comprehensive drive options: standard handles for manual operation, turbine heads for large-caliber, labor-saving adjustment, as well as precise electric actuators and efficient pneumatic actuators for automated control.

Key Features

Complete Fluoropolymer Lining

The interior body, disc edge, and flow path are fully lined with PTFE / PFA to protect against corrosive media.

Liner as Gasket / Face Seal

The PTFE liner can extend over the flange faces, replacing or reducing the need for separate flange gaskets in many installations.

Bubble-Tight Shutoff & Bi-Directional Seal

The valve achieves bubble-tight sealing in both flow directions, even in harsh chemical service.

Low Operating Torque

The smooth, low-friction lining reduces torque requirements, making both manual and automatic actuation easier.

Isolated Non-Wetted Components

All metal parts (body, stems, springs, bearings) remain isolated from fluid exposure, enhancing durability and reducing contamination risk.

Wide Material & Temperature Options

Available in ductile iron, stainless steel, carbon steel bodies; compatible with many flange standards. Typical service range from –20 °C to +150 °C (–4 °F to +302 °F).

Replaceable Liner / Seat System

Liner and sealing elements can be replaced in the field, minimizing downtime and life-cycle cost.

Typical Applications

Corrosive chemical and petrochemical processes

Acid / alkali handling systems

Chlorine, bleach, peroxide, brine, and aggressive media lines

Process utilities in chemical / pharmaceutical plants

Pulp & paper, mining, and fertilizer industries

Advantages

Exceptional chemical resistance and corrosion protection

Reliable, bubble-tight sealing even under aggressive conditions

Lower torque and energy cost in operation

No metal exposure to fluid—reduces contamination and corrosion

Simplified flange sealing (liner may act as gasket)

Long service life and industry-friendly maintenance

E-mail: wellwang557757@163.com

Tel/WhatsApp: +86 18961557757 +86 18018362100

Address: No. 2, Fandao Fanxing Road,Gaocheng Town, Yixing City,Jiangsu Province

Copyright © 2026 YEKE All Rights Reserved.

About Us

Production Equipment

Production Equipment

Certificate

Certificate

YEKE Group&Service

YEKE Group&Service

Brand story&What we stand for

Brand story&What we stand for

Products

Butterfly Valve

Butterfly Valve

Ball Valve

Ball Valve

Gate Valve

Gate Valve

Check Valve

Check Valve

Control Valve

Control Valve

Cryogenic Valve

Cryogenic Valve

Valve Actuator

Valve Actuator

News and events

Events

Events

News

News

Tel

Tel

+86 18961557757

+86 18018362100

Top

Top