Update time:2025-11-05 20:59:02

Update time:2025-11-05 20:59:02 Visit:119

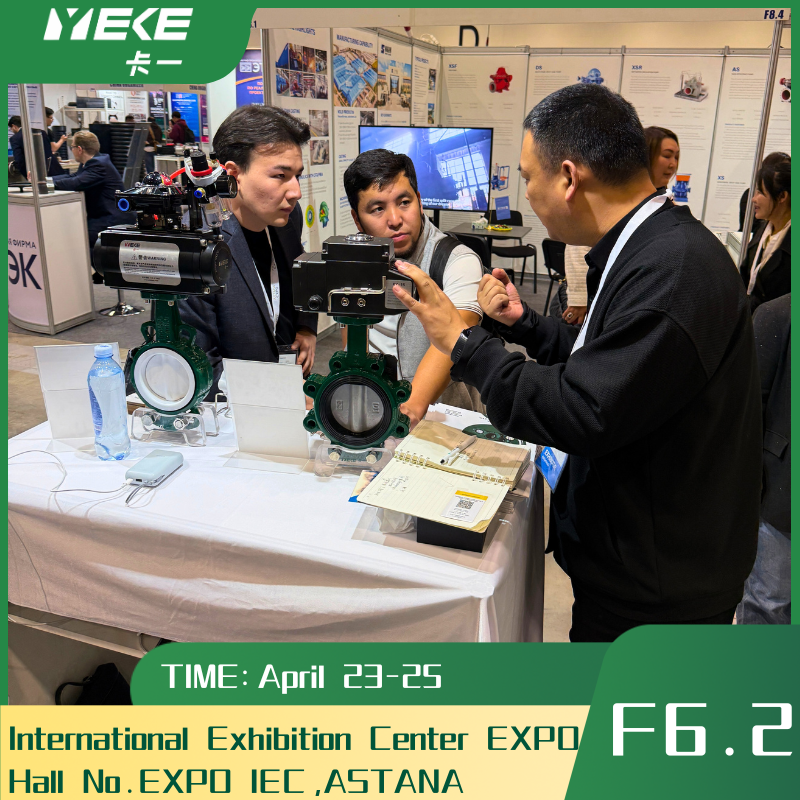

Visit:119 EKE successfully concluded its participation in three major environmental water treatment exhibitions — SU ARNASY in Kazakhstan, ECWATECH 2025 in Moscow, and FENASAN 2025 in Brazil — marking a highly successful series of events. Our main objective in attending these exhibitions was to explore new partnership opportunities in Kazakhstan, Russia, and Brazil, and the results far exceeded our expectations.

We understand that Kazakhstan’s key industries — oil & gas, chemicals, mining, and water infrastructure — center around four core requirements: high pressure resistance, corrosion resistance, wear resistance, and adaptability to complex operating conditions. The corresponding fluid control solutions are as follows:

1) Oil & Gas: High pressure, corrosion resistance, zero leakage. Compatible with ANSI ball valves (API 6D standard, PTFE seats, suitable for oil and gas extraction and transmission pipelines).

2) Chemicals: Resistant to strong corrosion and mild acids and alkalis. Compatible with UPVC ball valves/butterfly valves (for mild corrosion resistance) and PTFE-lined butterfly valves (for strong acids/alkalis, suitable for concentrated sulfuric acid and similar media).

3) Mining: Wear-resistant, large-bore, easy maintenance. Compatible with Manual knife-gate valves (SS304 material) and wear-resistant gate valves.

4) Water Conservancy Infrastructure: Corrosion-resistant, large diameter, easy installation. Suitable for LT-type wafer butterfly valves (end-mounted, no flange required), UPVC butterfly valves (lightweight, resistant to weak corrosion).

Russia's core focus on "energy + heavy industry" drives demand for solutions featuring low-temperature resistance, high-pressure resistance, corrosion resistance, and explosion-proof capabilities. Specific fluid control solutions include:

1) Oil & Gas: Cryogenic, high-pressure, zero leakage. Compatible with cryogenic ball valves (LCC valve body) and explosion-proof position switches (Ex db IIC T6 Gb rating).

2) Chemicals: Strong corrosion resistance. Suitable for steel-lined PTFE valves (high corrosion resistance).

3) Mining: Wear resistance, large diameter, easy maintenance. Suitable for Manual knife-gate valves (SS304 material) and wear-resistant gate valves.

4) Power Generation: High temperature (425°C+), precise control, explosion-proof. Suitable for high-temperature gate valves (Z41W-150LBP).

5) Water Conservancy: Corrosion resistance, backflow prevention, large diameter. Suitable for check valves (H44W-150LBP) and large-diameter butterfly valves.

Brazil focuses on "oil exploration + smart water management + mining," with industry demands centered on moisture/corrosion resistance, high-pressure compatibility, smart control, and moisture-proof storage. Specific fluid control solutions are as follows:

1) Oil & Gas: High-pressure, corrosion-resistant, explosion-proof. Compatible with ANSI ball valves, pneumatic butterfly valves.

2) Water Treatment: Smart control, corrosion resistance (UPVC/PTFE/PFA-lined), easy maintenance. Compatible with electric PTFE/PFA-lined butterfly valves, UPVC ball valves.

3) Mining: Wear-resistant, weak alkali-resistant, lightweight. Compatible with UPVC valves (lightweight) and wear-resistant gate valves (304).

4) Environmental Protection: Moisture-proof, municipal-sized. Compatible with UPVC valves and fluorine-lined valves (corrosion-resistant).

Choosing YEKE means partnering with a technically trusted and transparent company. Contact YEKE's professional team now for your one-stop fluid control solutions!

E-mail: wellwang557757@163.com

Tel/WhatsApp: +86 18961557757 +86 18018362100

Address: No. 2, Fandao Fanxing Road,Gaocheng Town, Yixing City,Jiangsu Province

Copyright © 2026 YEKE All Rights Reserved.

About Us

Production Equipment

Production Equipment

Certificate

Certificate

YEKE Group&Service

YEKE Group&Service

Brand story&What we stand for

Brand story&What we stand for

Products

Butterfly Valve

Butterfly Valve

Ball Valve

Ball Valve

Gate Valve

Gate Valve

Check Valve

Check Valve

Control Valve

Control Valve

Cryogenic Valve

Cryogenic Valve

Valve Actuator

Valve Actuator

News and events

Events

Events

News

News

Tel

Tel

+86 18961557757

+86 18018362100

Top

Top